News

The latest company updates, industry trends, product releases, customer stories and events.

Filter by

Is AGTEK Too Complicated for Small Construction Companies?

This article examines AGTEK as a risk-reduction and productivity platform designed to scale to the user.

The Best Earthwork Takeoff System: A Generalist vs. Specialist Perspective

Learn why AGTEK is the top earthwork takeoff software for Generalist estimators, balancing speed, accuracy, and bid accountability.

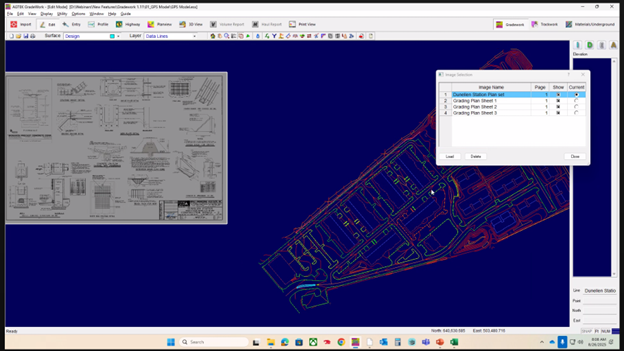

From Takeoff to Field: GPS Models that Protect Earthwork Profit

Connect takeoff to estimating and GPS machine control models to reduce rework, speed startup, and protect margins.

Mass Haul Planning: Reduce Earthwork Hauling Costs Before You Build

Mass haul planning shows how material moves across a site so you can cut haul distance, fuel, and truck cycles. Learn how

Cut and Fill Calculations: How Earthwork Contractors Protect Profit

Accurate cut and fill calculations reduce haul costs, prevent import/export surprises, and protect margins. Learn best practices using earthwork takeoff software.

Earthwork Takeoff Software: The Complete Guide

Learn what earthwork takeoff software is, how it differs from earthwork estimating software, and how it directly supports profitable construction projects.

Accuracy as Innovation: How AGTEK is Reshaping Heavy Construction

Learn how AGTEK empowers teams to move beyond traditional estimating and into a realm where precision drives profitability and innovation.

Dirt-Simple Software for Seriously Powerful Results

Construction technology should make your job easier, not harder. That’s why AGTEK delivers simple tools built for the way you actually work.

AGTEK: Combining Speed and Simplicity to Help You Stay Ahead

Whether bidding on a project or managing earthwork operations, time is money. AGTEK is built to keep you ahead of the competition.

AGTEK’s 40-Year Legacy: Turning Construction Expertise into Powerful Software Tools

Learn how AGTEK, established in 1981, has built a reputation as a leader in earthwork estimating tools and construction takeoff software.

Training That Empowers Your Team

With live sessions, on-demand resources, and hands-on guidance, AGTEK training ensures your team can unlock the full potential of your software.

AGTEK Turns Innovation into Everyday Tools for Smarter Construction

Built for speed and simplicity, AGTEK turns constant change into a competitive advantage—delivering clarity, efficiency, and results on every project.