Your GPS Model Plays a Vital Role in Construction Quality

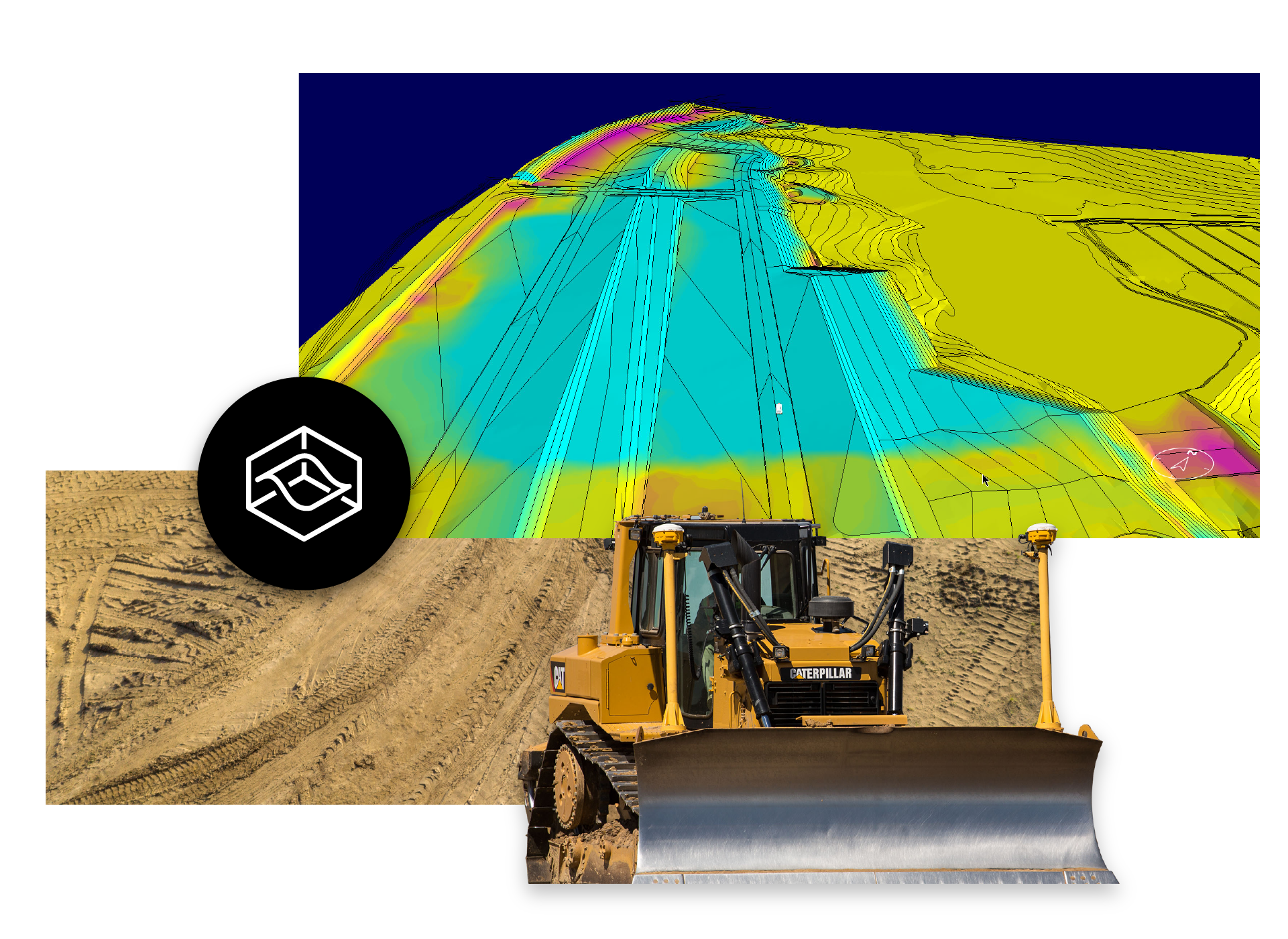

The Grade Control model is used by GPS machine control systems for precision grading and by grade checkers to confirm compliance with specifications.

A simple and quick method for building models

Modeling applies to the physical representation of the finished project and tracking the construction processes and progress of how to get there. AGTEK solutions enable models to be created based on a variety of data including PDF and CAD. Machine and Grade Control models can be created for all major equipment models and technology manufactures including John Deere, Caterpillar, Komatsu, Trimble, Topcon, and Leica Geosystems. Whether optimizing areas of cut and fill, planning hauls, refining the construction process, or creating the surface model your GPS machine control system requires, AGTEK has a solution for you.

Software for grade control 3D model creation

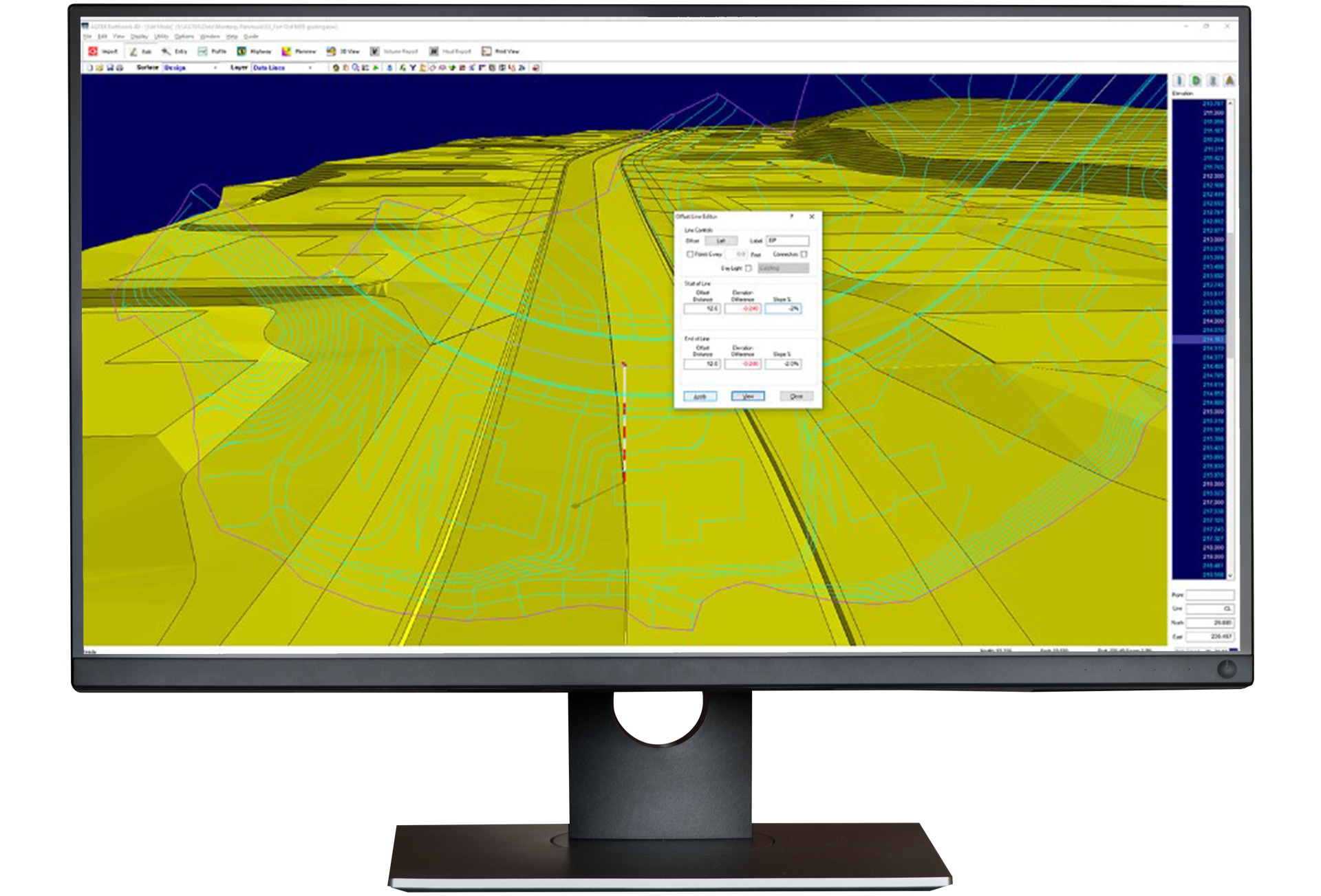

The ability to visualize the project as it will appear upon completion (“What you see is what you build”) reinforces the accuracy of the models created, thereby reducing errors and optimizing construction strategies. AGTEK’s modeling solutions not only focus on traditional tasks like cutting and filling but also enhance planning for material hauls and streamline the overall construction workflow.

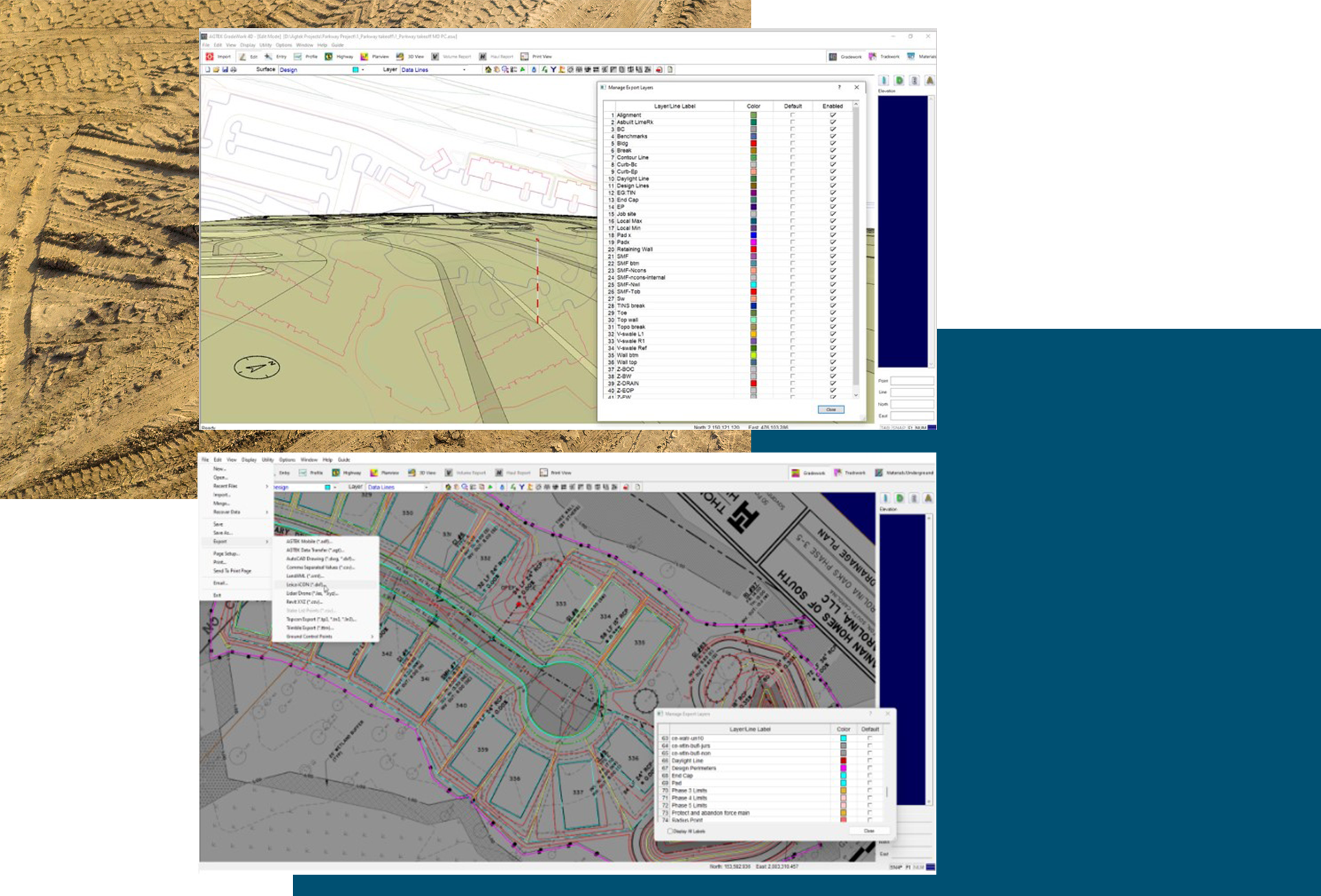

Data for building grade control models

From the outset, AGTEK’s software integrates data from diverse sources—whether from private engineering firms or government agencies—to craft detailed, constructible models. These models facilitate both finished and subgrade constructions by calculating accurate material volumes necessary for each phase.

Creating models for mixed fleets

AGTEK’s software is designed to support various construction machinery, including dozers, graders, scrapers, excavators, and curb and gutter pavers. Its intuitive interface simplifies the modeling process, making it accessible even to those new to using GPS-based machine control systems. With compatibility across various data formats, AGTEK’s solutions cater to a mixed fleet, providing a comprehensive modeling tool for all equipment types.

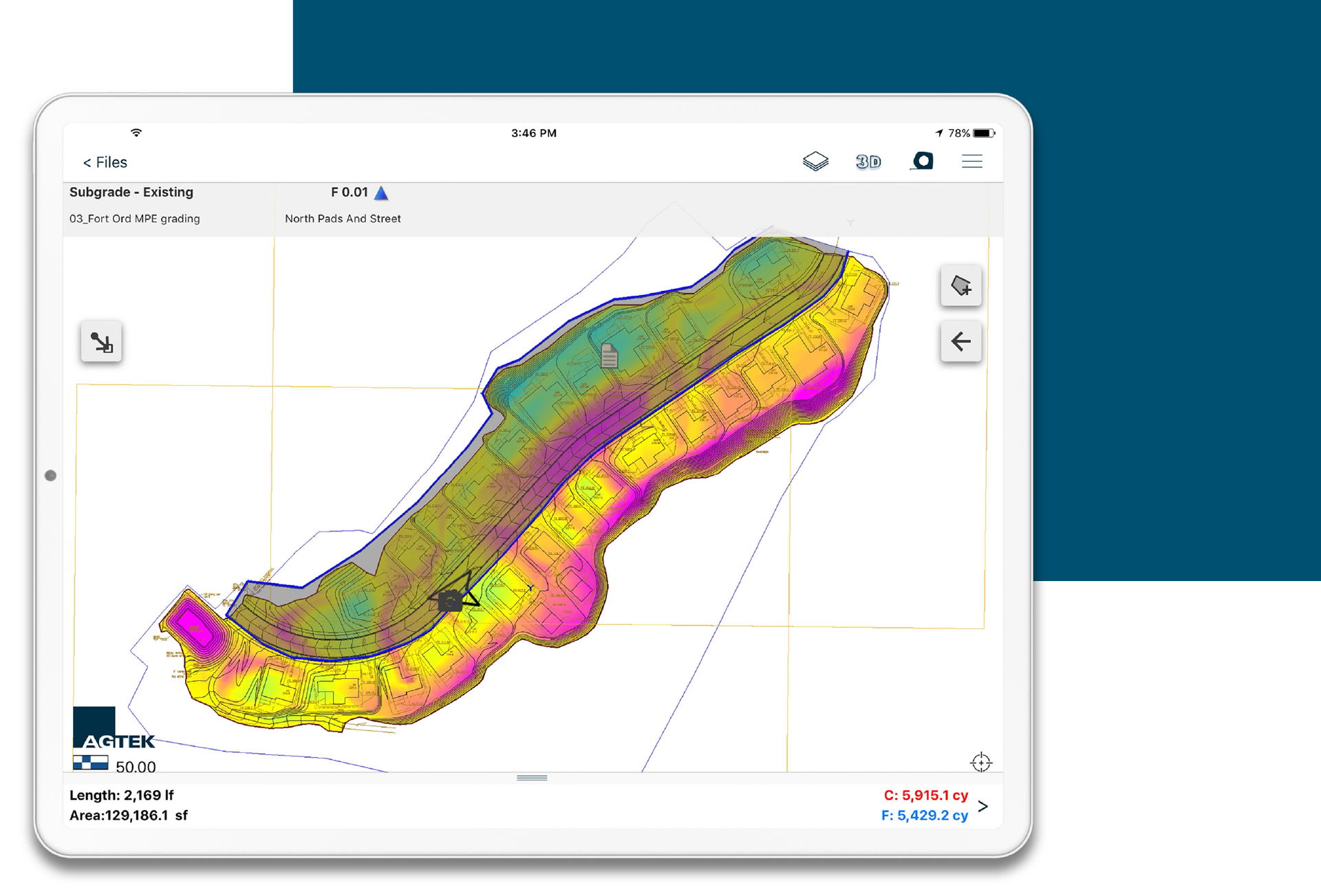

Measuring construction process against the model

As the project progresses, real-time data from machine control systems, grade checkers, or drones is integrated into the AGTEK software, allowing for swift and precise progress tracking. This updated information about cut-fill volumes is made readily available to project teams, enhancing decision-making in the field through mobile apps and allowing seamless export to third-party systems. This connectivity ensures that every team member is informed and can make the best possible decisions based on the latest data.

Get in touch with our team

Let us know if you have questions about AGTEK sales, training, or products. A representative will be in touch soon.

-

Connect with an AGTEK expert

-

Get your questions answered fast

-

Schedule a strategy call

-

Start winning more jobs with AGTEK